TPU Repro and Compounding (Thermoplastic Polyurethane)

Plastmax Polyurethane (TPU) Blends and Compounds are engineered materials created by combining polyurethane with other polymers, additives or fillers to enhance specific properties or tailor them for particular applications. These Compounds extend the versatility of Polyurethane (TPU), offering unique combinations of performance characteristics.

Key Features

- Customizable Properties: Adjust hardness, elasticity, thermal stability, and more.

- Improved Performance: Enhanced abrasion resistance, impact strength, and chemical compatibility.

- Ease of Processing: Suitable for various manufacturing methods, including injection molding and extrusion.

- Eco-Friendly Options: Blends can include recycled or bio-based materials for sustainable solutions.

- Cost-Effectiveness: Optimized blends can reduce material costs without compromising performance.

- Compatibility: Can bond with a wide range of materials like metals, plastics, and fabrics.

Types

TPU-Polyether Blends:

- Offers high flexibility, low-temperature resistance, and hydrolysis stability.

- Applications: Hoses, gaskets, and outdoor products.

TPU-Polyester Blends:

- Delivers excellent mechanical strength and wear resistance.

- Applications: Conveyor belts, industrial rollers, and automotive components.

TPU-Polycarbonate Blends:

- Improves rigidity and thermal stability while retaining toughness.

- Applications: Electronics, protective cases, and structural parts.

TPU-Rubber Compounds:

- Combines elasticity and shock absorption with TPU's durability.

- Applications: Wheels, vibration dampeners, and impact-resistant components.

TPU-Nylon Blends:

- Enhances strength, chemical resistance, and dimensional stability.

- Applications: Automotive parts, cables, and high-performance textiles.

Customization and Additives

Plastmax Polyurethane (TPU) Blends and Compounds can be modified to achieve specific functionalities:

- Colorants: Wide range of pigments for aesthetic and branding purposes.

- Reinforcements: Glass fibers, carbon fibers, or mineral fillers for enhance stiffness, thermal conductivity and/or electrical properties.

- Additives: UV stabilizers, antimicrobial agents, flame retardants and anti-static agents.

Advantages

- Versatility: Suitable for diverse industries and applications.

- Durability: High wear and tear resistance, even in extreme conditions.

- Sustainability: Options for recyclable or biodegradable materials.

- Improved Performance: Tailored properties meet specific functional requirements.

- Custom Design: Additives like UV stabilizers, flame retardants, or anti-static agents provide tailored solutions.

Applications

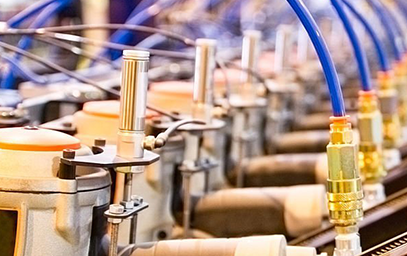

Automotive Industry:

- Pneumatic pressure pipes & tubes for oil transportation under high pressure.

- Lightweight panels, Bushings, and Seals for improved fuel efficiency and durability.

- Airbag covers and lightweight structural components.

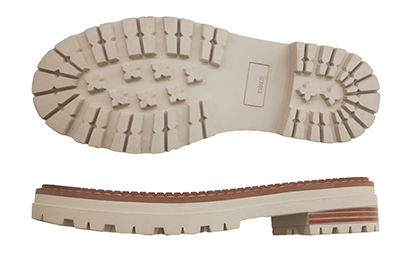

Footwear:

- Soles, midsoles, and upper materials with optimized flexibility and durability.

Construction:

- Insulation materials, adhesives, and protective coatings for enhanced building performance.

Consumer Goods:

- Phone case, Flexible foams for mattresses and furniture, etc.

Electronics:

- Flexible connectors, wire sheathing, and protective housings.

Medical:

- Tubing, breathable films, and device components requiring biocompatibility.

Industrial Applications:

- Conveyor belts, Rollers, Hoses, and protective linings in harsh environments.

Why Choose Plastmax TPU?

TPU blends and compounds offer a perfect balance of performance, flexibility, and sustainability. Their ability to adapt to varied applications makes them a preferred choice in industries ranging from automotive and electronics to healthcare and consumer goods.

Conclusion

Polyurethane blends and compounds are ideal for industries seeking innovative solutions that combine performance, durability, and cost-effectiveness. With their adaptability and wide range of customization options, they continue to drive advancements across diverse sectors.

Contact PLASTMAX (THAILAND) CO. LTD. to develop more about how Polyurethane (TPU) Blends and Compounds can meet your specific application needs!

Applications

Automotive

Automotive

Automotive

Automotive

Automotive

Consumer Products

Consumer Products

Footwear

Footwear

Footwear

Footwear

General

General

General

General

General

General

General

Industrial

Industrial

Industrial

Industrial

Industrial

Medical